- GST NO. : 27AACCP2652G1ZJ

View Mobile Number

| Business Type | Manufacturer, Exporter, Supplier |

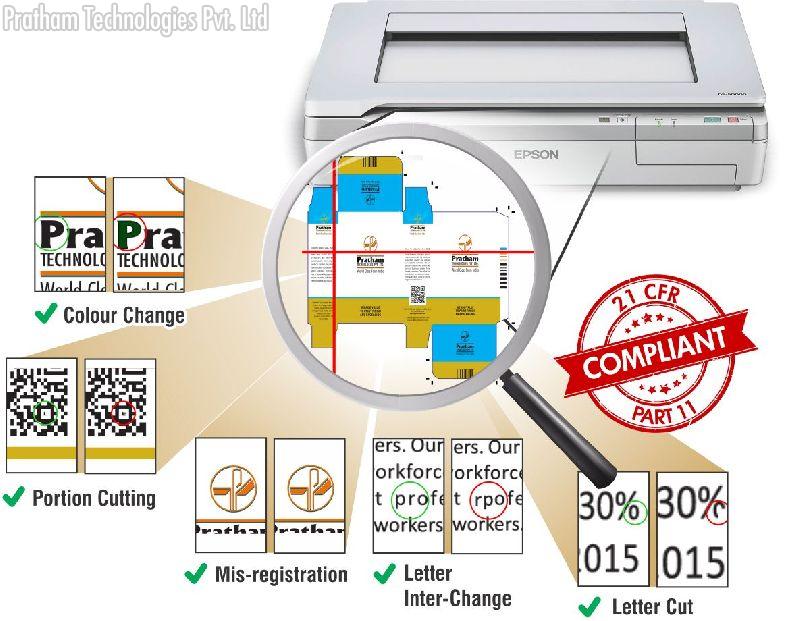

Pharma companies operating in the regulated markets are very fussy. Not only with the medicines that they supply but also with the accuracy and reliability of the instructions that go on the packaging of the medicines including cartons, labels and patient information leaflets. A tiny error in the text or a missing dot can lead to drug recalls resulting in huge losses for the Pharma companies.

The drug regulatory bodies such as US FDA and EMEA are extremely particular when it comes to accuracy of the printed literature and packaging that accompany the drug. This makes it pertinent for the Pharma companies to be able to make the leaflets, cartons and labels flawless and also check and reassure the flawlessness.

This calls for the need for automation; smart automation that can detect minute deviations in print in a fast and reliable way. This responsibility lies not only with the pharma companies but also with the pharma packaging converters.

Pharmacist Filling Prescription Pharmacy Drugstore

Today, the pharma packaging converters are under price and performance pressure. They are faced with challenges of time constraints, short-run high-frequency print jobs, manpower training and retaining trained manpower.

For a pharma converter, avoiding printing mistakes at every stage of the operation is significant. A reliable converter is the one who cross-checks the ready-to-print artwork PDF file with the original customer-approved artwork PDF file before printing. Going further, the scanned file of first prints should also be matched against the original customer-approved PDF file. That’s how a converter can assure his customer about 100% accuracy of the print product.

Silent features:

- User-friendly operation

- Requires minimum time to check the all the ups in a single sheet

- Quality and consistency in checking minute defects

- Compare multi-ups sheet with single ups PDF file (Approved by Pharma or FMCG Customers)

- Quick job setting

- Auto Skew Correction (At least 5 Deg.)

- Usable with any Fonts

- Preciseness to detect smaller defects within lesser list no. of defects

- Barcode and Pharma code decoding

- Foil Checking is separate system to check the reflective medicine foils

- Braille decoding is optional system

Looking for "Proofreading Software" ?

Explore More Products